Our industry

Healthcare

With our integrated healthcare logistics solutions, we connect you more closely with the point of care and your patients. Our focus is on efficiently designing and developing your sales and distribution channels to the highest quality standards. From state-of-the-art automation solutions to individual patient delivery, we ensure the safety of your patient care through seamless distribution of pharmaceuticals and medical devices. We deliver quality of life!

Supply Chain Management in Healthcare

We take over the healthcare supply chain management of various product categories for our clients. Our centrally controlled quality assurance and our globally standardized IT system minimize process complexity and offer you standardized reporting with maximum transparency. For the individual product categories, we are able to guarantee a wide variety of temperature ranges - from ambient (15-25 degrees) to ultra-low temperature (-80 degrees), depending on the requirements.

Our healthcare logistics solutions

Pharma logistics

Inventory management at the point of care

E-commerce fulfillment

Cell and gene therapy solutions

Clinical Trial Supply

Direct-to-Patient

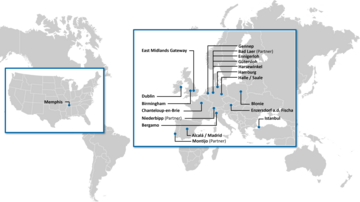

Strong international site network

We are your partner when it comes to the internationalization of your healthcare distribution models. With our centralized operation, a standardized IT system based on a fully integrated SAP system and a centralized quality management structure we provide a flexible framework for individual and harmonized solutions.

Our healthcare distribution centers are designed specifically for the pharmaceutical and medical technology industry and meet all necessary requirements for the warehousing and distribution of sensitive products.

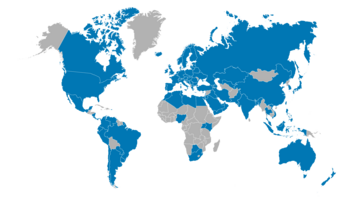

Worldwide Multichannel Distribution

We serve various healthcare sales channels from our pharmaceutical warehouses in order to ship medical products worldwide to: hospitals, pharmacies, doctors, laboratories, patients and wholesalers as well as distributors. We provide optimal support for manufacturers’ multi- and omni-channel strategies, shipping goods from one warehouse which facilitates the creation of standardized structures, a higher level of transparency, optimized processes and stock and reduces costs. We offer flexible transport options in over 127 countries - by active cold chain linehaul or passive delivery. We meet delivery times, in many regions also as same-day delivery.

Our healthcare quality standards

Our services are based on international healthcare quality assurance systems. We have mandatory licenses and certifications to ensure the end-to-end security of your supply chain.

We are certified:

- ISO 13485

- ISO 9001

- GMP

- GDP

- Known consignor (air freight security)